Floyd Rose USA-Series: New Tremolos, 3D Printed Locking Nuts & CNC Saddles!

Floyd Rose has once again pushed the boundaries of guitar hardware with its latest release. The brand is introducing a groundbreaking product crafted using advanced manufacturing techniques. This new addition to their lineup is designed to elevate performance and precision for musicians everywhere.

At the heart of this innovation is a cutting-edge process that ensures superior accuracy and consistent quality. By transitioning from traditional methods to modern technology, Floyd Rose has set a new standard in the industry. Each component is meticulously crafted to meet the highest standards of durability and functionality.

This launch not only highlights the brand’s commitment to excellence but also showcases its dedication to innovation. Stay tuned as we dive deeper into how this product is reshaping the future of guitar hardware.

Evolving Tradition: The Floyd Rose Story

From its humble beginnings, Floyd Rose has redefined guitar hardware excellence. For over four decades, the brand has been a driving force in the music industry, blending tradition with cutting-edge technology. Its legacy is built on a foundation of precision, durability, and innovation.

From Iconic Beginnings to Modern Innovation

Floyd Rose started with a simple yet revolutionary idea: to improve the performance of guitars. The brand’s original designs quickly became a favorite among musicians, offering unmatched tuning stability. Over the years, it has continued to evolve, embracing modern techniques while staying true to its roots.

Each piece of hardware reflects a commitment to quality and forward-thinking design. From its early days to today, Floyd Rose has remained a symbol of excellence in the world of music.

Revolutionizing Production with 3D Metal Printing

A new era of manufacturing is transforming how guitar components are made. By leveraging advanced metal printing, the industry is achieving levels of precision and efficiency never seen before. This innovative method is replacing outdated techniques, offering musicians hardware that meets the highest standards of quality.

The process begins with powdered metal, which is meticulously layered using cutting-edge printing technology. Each layer is fused together through sintering, ensuring a solid and durable structure. The final step involves CNC kiss-cutting, which adds precision and fine details to the component.

This approach guarantees tighter tolerances and exact specifications, making it ideal for intricate guitar hardware. The result is a product that performs flawlessly, even under the most demanding conditions.

Floyd Rose continues to innovate with its latest hardware release, proudly crafted in the USA. (available summer 2025) This new locking nut combines steel and advanced printing techniques to deliver unmatched durability and precision. Each component is designed to meet the needs of musicians, ensuring consistent performance.

President Andrew Papiccio emphasizes the importance of full manufacturing control. “Our process ensures tighter specifications and enhanced quality,” he says. By keeping production local, Floyd Rose maintains rigorous standards and supports American craftsmanship.

The locking nuts are available in a defined range of sizes to accommodate various fretboard radii. This flexibility ensures a perfect fit for any guitar, enhancing playability and tuning stability. Whether you’re a professional or a hobbyist, these nuts are built to perform.

Multiple Radii Options for Optimal Fretboard Fit

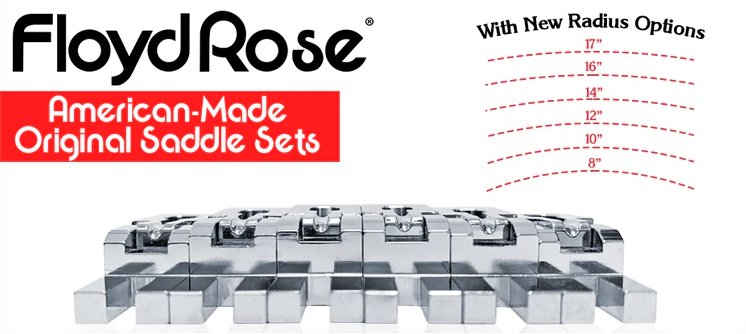

Musicians can choose from a range of radii options to match their fretboard curvature. Available in 8”, 10”, 12”, 14”, 16”, and 17”, these saddles are designed to eliminate compatibility issues. This flexibility allows players to achieve their desired action and intonation effortlessly.

| Radius Option | Best For |

|---|---|

| 8” | Vintage-style fretboards |

| 10” | Classic designs |

| 12” | Modern setups |

| 14” | Versatile playability |

| 16” | Extended range guitars |

| 17” | Flat fretboards |

With new technology at its core, Floyd Rose is setting a higher standard for guitar hardware. The combination of steel and advanced printing ensures each locking nut is robust and reliable. This is innovation you can trust, made right here in the USA.

Advantages Over Traditional Lost Wax Casting

Compared to the older lost wax casting method, 3D metal printing offers significant benefits. Production speed is dramatically increased, allowing for faster turnaround times. Consistency is also improved, with each piece meeting the same high standards.

Quality control is another major advantage. The new process minimizes errors and ensures every component is perfect. By integrating this technology, manufacturers can deliver superior products that musicians can rely on.

This shift in production methods is not just about efficiency—it’s about setting a new benchmark for excellence in guitar hardware. The future of manufacturing is here, and it’s changing the game for everyone involved.

Precision CNC Machined Saddles

Precision-engineered guitar components are essential for achieving optimal sound and playability. The latest advancements in CNC saddles bring unmatched accuracy and durability to modern hardware. These components are designed to enhance performance, ensuring every note resonates with clarity.

Each saddle is crafted using state-of-the-art CNC machining, ensuring tight tolerances and consistent quality. This process eliminates the need for traditional shimming, providing a seamless fit for various fretboard shapes. Premium hardened tool steel is used to enhance durability, while smooth plating finishes reduce friction during play.

Quality control measures are implemented at every stage of production. From material selection to final calibration, each saddle undergoes rigorous testing to meet the highest standards. This meticulous approach ensures that every part performs flawlessly under intense conditions.

Engineered to align with specific fretboard curvatures, the Original saddle sets now come in multiple radius options, eliminating the need for individual saddle shims. Alongside the traditional 12” radius, Floyd Rose Original Saddles are now available in 10”, 14”, 16”, and 17” radii. Constructed from premium tool steel with precision CNC machining, these saddles undergo heat treatment and plating to endure the rigors of even the most intense performances. Visit Floyd Rose to check out more.

Behind the Scenes: Inside the USA Production Facility

Inside the facility, cutting-edge technology meets expert craftsmanship. This production center in North Carolina is where every component is brought to life with precision and care. From advanced machinery to skilled engineering, the process ensures top-tier quality for musicians worldwide.

State-of-the-Art Machining in North Carolina

The facility houses four Haas VF-series CNC machines, known for their precision and reliability. These machines play a crucial role in crafting components that meet the highest standards. The dedicated metal finishing department adds the final touch, ensuring durability and performance.

Every part undergoes rigorous testing to guarantee consistency. This attention to detail is what sets the facility apart, making it a leader in manufacturing excellence. The integration of modern techniques like CNC machining ensures that every component is built to last.

In-house production allows for faster turnaround times and improved reliability. This commitment to precision and quality is a testament to the facility’s dedication to excellence. By combining traditional craftsmanship with modern technology, they continue to set new benchmarks in the industry.

Enhanced Consistency and Superior Fit

Consistency is another major advantage. With advanced production methods, every piece of hardware meets exacting standards. This means musicians can trust their equipment to perform reliably, even after years of use. The result is a setup that stays precise, reducing the need for frequent adjustments.

These improvements also offer more options for players. Whether you’re customizing your guitar or fine-tuning your setup, the flexibility provided by modern hardware makes it easier to achieve the sound and feel you want. It’s all about giving musicians the tools they need to excel.

By focusing on precision and quality, this new wave of hardware technology is setting a higher standard. It’s not just about innovation—it’s about creating a better experience for every guitarist. From fit to control, every detail is designed with the player in mind.

Floyd Rose & Schaller: The Shift to US Production

While neither Floyd Rose nor Schaller have published an extensive, point-by-point explanation for a possible split, there are several widely acknowledged reasons that help illustrate why Floyd Rose may chose to end production with Schaller in Germany and bring manufacturing back to the United States:

-

Greater Control Over Manufacturing:

By transitioning to in-house or domestic production, Floyd Rose gained direct oversight of every aspect of the manufacturing process. This move makes it easier to implement design updates, fine-tune quality control, and ensure that every product meets their exact specifications. -

Quality Assurance and Consistency:

Although Schaller once had a strong reputation for precision, ending the licensing arrangement allows Floyd Rose to oversee quality assurance more closely, from material sourcing to final inspection. This hands-on approach can help maintain the high standards that players expect from Floyd Rose hardware. -

Streamlined Supply Chain and Availability:

Relying on an overseas partner sometimes leads to longer lead times or shipping constraints. By moving production to the USA, Floyd Rose likely aims for faster turnaround and a more responsive supply chain. This step also enables quicker restocks and custom orders. -

Desire to Innovate and Modernize:

Bringing manufacturing under the Floyd Rose umbrella can speed up R&D. New designs—such as CNC-milled saddles, 3D-printed parts, and broader radius options—can be more rapidly prototyped, tested, and brought to market when everything is consolidated in one facility. -

Branding and “Made in USA” Appeal:

Many guitarists place a high value on hardware produced in the United States. By emphasizing that Floyd Rose products are now “Made in the USA,” the company can cater to musicians seeking domestically manufactured gear and tap into a well-established market preference. -

Contractual or Licensing Conclusion:

It’s also possible the long-running licensing agreement simply concluded or reached a stage where continuing under Schaller no longer aligned with Floyd Rose’s evolving business goals.

In short, Floyd Rose’s decision to part ways with Schaller appears to be driven by a mix of strategic, logistical, and quality-control reasons that ultimately led them to establish a more direct, USA-based production model. Nik from The Axe Guitar does a great job explaining this.

Final Reflections on a New Chapter in Guitar Hardware

The future of guitar hardware is here, blending tradition with cutting-edge innovation. The advanced printing process redefines quality and consistency, ensuring every nut and component meets precise specifications. This marks a transformative moment for the industry.

By merging historical legacy with modern technology, the new Floyd Rose product lines promise unmatched reliability. Rigorous quality control underpins each piece, delivering hardware built for precision and longevity. This evolution allows musicians to focus on their craft, trusting their equipment to perform flawlessly.

Looking ahead, the plan is to continue innovating in design and manufacturing. The new Floyd series sets a higher standard, offering guitarists superior performance and durability. This is more than an upgrade—it’s a new chapter in guitar hardware, built to inspire confidence and creativity.